- Call Us Today!

- +86 519-88123456

- info@ptfe-pcb-laminate.com

Advantages of PTFE PCB Laminate in Electronics

12/03/2024

Understanding Diclad 880 Laminate Properties

12/30/2024In the realm of electronics manufacturing, materials matter. One such material, PTFE Prepreg, has become a cornerstone in the industry.

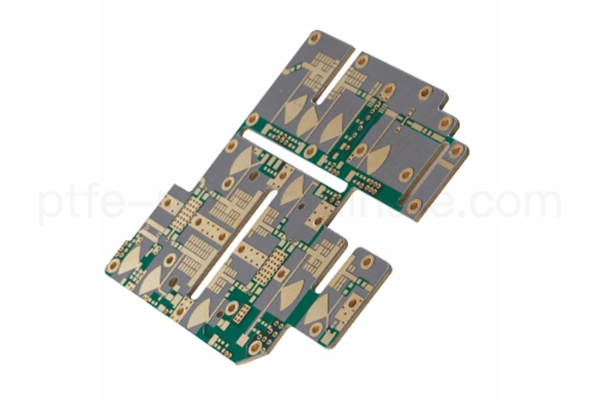

PTFE Prepreg, a composite made from PTFE coated fiberglass fabric, is known for its exceptional properties. It’s a key player in the production of RF & Microwave PCBs, thanks to its superior electrical insulation and thermal stability.

But what makes PTFE Prepreg so special? And how is it manufactured?

This article aims to answer these questions, providing a comprehensive understanding of PTFE Prepregs. We’ll delve into the manufacturing process, from the coating of fiberglass fabric to the pressing of PTFE laminate.

We’ll also explore the benefits of PTFE Prepregs and their applications across various industries. By the end, you’ll have a solid grasp of why PTFE Prepregs are a preferred choice in electronics manufacturing.

So, let’s embark on this journey of understanding the benefits of PTFE Prepreg.

The Basics of PTFE Prepreg

Understanding PTFE Prepreg begins with its composition. At its core, it is a composite material. This composite is crafted from PTFE coated fiberglass fabric, enhancing both performance and durability.

What sets PTFE Prepreg apart is its use in the electronics industry, especially in RF & Microwave PCBs. The material’s advanced composition offers electrical insulation and excellent thermal properties.

The distinct attributes of PTFE Prepreg also extend to moisture resistance and chemical stability. These characteristics ensure that PTFE Prepregs remain reliable across a range of conditions.

When considering PTFE Prepreg, one should note its comprehensive application capabilities. It supports not just current industry needs, but also future technological advancements.

In summary, PTFE Prepreg is a high-performance material with diverse uses in electronics and beyond. Here are the core aspects of PTFE Prepreg to remember:

- Constructed from PTFE coated fiberglass fabric

- Key component in RF & Microwave PCBs

- Provides electrical insulation and thermal stability

- Moisture and chemically resistant

- Adaptable to future tech needs

What is PTFE Prepreg?

PTFE Prepreg is a prepreg formed by impregnating fiberglass fabric with a PTFE resin. This combination results in a unique composite material.

The process involves coating the fiberglass with PTFE dispersion and drying it into a prepreg sheet. This material is essential in the electronics field, especially where high-frequency performance is required.

PTFE Prepreg is part of the broader family of advanced composites, known for boosting efficiency in modern manufacturing.

Key Properties of PTFE Prepreg

PTFE Prepreg is lauded for its top-tier dielectric properties, making it indispensable in high-frequency applications. This prepreg boasts remarkable thermal stability, suitable for a wide range of operating temperatures.

Its resistance to moisture absorption ensures consistent performance even in varying environments. PTFE Prepreg also excels in electrical insulation, crucial for maintaining signal integrity.

Chemically resistant, PTFE Prepreg protects against harsh chemicals, prolonging product lifespan. Its low loss tangent minimizes signal loss, making it ideal for high-frequency circuits.

Here are the key properties outlined:

- Excellent dielectric properties

- High thermal stability

- Moisture resistant

- Superior electrical insulation

- Chemical resistance

Overall, the properties of PTFE Prepreg make it a key material in both established and emerging electronics applications.

Manufacturing Process of PTFE Prepreg

The creation of PTFE Prepreg is a meticulous process involving several key stages. Each step is crucial in ensuring the final material’s performance characteristics. Understanding these steps can empower manufacturing managers to optimize production efficiency and quality.

The process begins with applying a PTFE dispersion to fiberglass fabric. This stage sets the foundation for the prepreg’s properties.

After coating, the fabric undergoes drying and semi-curing. This ensures even distribution of PTFE and prepares it for further processes.

The coated fabric is then layered with copper foil. Pressing these layers involves precise control of temperature and pressure.

Finally, the pressed material forms copper clad laminates. The precision in this stage impacts the prepreg’s electrical and mechanical attributes.

- Application of PTFE dispersion

- Drying and semi-curing

- Layering with copper foil

- Pressing to form laminates

Coating and Drying Fiberglass Fabric

The PTFE prepreg process starts with careful coating. PTFE dispersion is applied to fiberglass fabric, creating a uniform layer. This coating step is vital for the prepreg’s functional attributes.

Drying follows, removing solvents and solidifying the PTFE coating. This step ensures even PTFE distribution on the fiberglass fabric.

Semi-curing then begins, allowing the coated fabric to achieve proper tackiness. Proper semi-curing prepares the fabric for the pressing stage.

Pressing into Copper Clad Laminates

With prepreg ready, pressing is the next critical step. Copper foil is carefully layered with the PTFE-prepregged fabric.

This assembly is then subjected to heat and pressure. Precise control here ensures the laminate’s optimal performance.

Pressing produces the final copper clad laminate. This resulting product is vital in numerous electronics applications, ensuring reliability and efficiency.

Advantages of PTFE Prepreg in RF & Microwave PCBs

PTFE Prepreg offers several key benefits that make it ideal for RF and microwave PCB applications. Its unique properties enhance both product performance and manufacturing efficiency.

One of the primary benefits is its superior electrical insulation. This characteristic is crucial for maintaining signal integrity in high-frequency applications.

PTFE Prepreg also offers excellent thermal stability. This allows it to perform across a wide range of temperatures without degrading.

Moreover, the material is chemically resistant. This means it can withstand harsh environments and substances without compromising its integrity.

Using PTFE Prepreg can significantly improve the reliability of RF and microwave PCBs.

- Superior electrical insulation

- Excellent thermal stability

- Chemical resistance

- Improved reliability

- Enhanced signal integrity

Superior Electrical Insulation and Signal Integrity

PTFE Prepreg is renowned for its outstanding electrical insulation. This attribute ensures minimal signal loss in high-frequency circuits.

The material’s low dielectric constant contributes to excellent signal integrity. This makes PTFE Prepreg a preferred choice for RF and microwave PCBs.

Overall, PTFE Prepreg ensures consistent electrical performance. This is vital for both precision and reliability in demanding electronic applications.

Thermal Stability and Chemical Resistance

Thermal stability is another standout feature of PTFE Prepreg. The material maintains its properties even at high temperatures.

This stability makes PTFE Prepreg suitable for use in challenging thermal environments. It offers consistent performance regardless of temperature changes.

Chemical resistance further enhances its versatility. PTFE Prepreg resists degradation when exposed to various chemicals, protecting the PCB’s functionality.

Applications Across Industries

PTFE Prepreg is valued across diverse industries due to its versatile properties. Its use extends far beyond just RF and microwave PCBs.

Industries capitalize on its unique benefits for various high-performance applications. This material’s adaptability makes it a favorite among engineers.

Here are some key industries where PTFE Prepreg is commonly used:

- Aerospace

- Telecommunications

- Medical Devices

- Industrial Processing

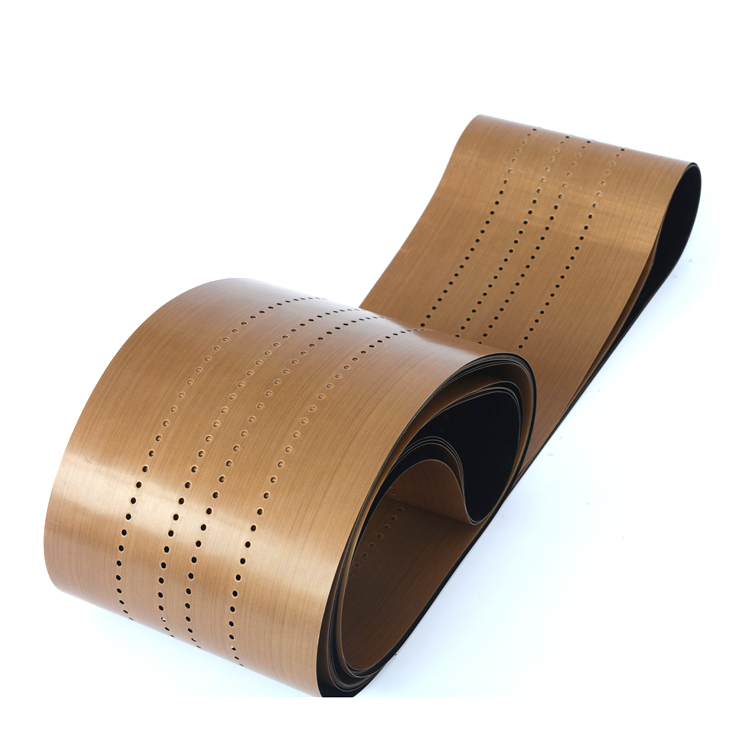

- Food Conveyance

Aerospace, Telecommunications, and Beyond

In aerospace, PTFE Prepreg contributes to the manufacturing of reliable components capable of withstanding harsh conditions. Its thermal and chemical resistance is crucial for aerospace applications.

Telecommunications sectors also benefit significantly from PTFE Prepreg. It supports the development of high-frequency communication devices with optimal signal integrity.

Beyond these, PTFE Prepreg finds applications in emerging fields like medical devices and industrial processing. Its diverse capabilities continue to drive its growth in these innovative fields.

Overcoming Challenges and Ensuring Quality

Manufacturers often face challenges when working with PTFE Prepreg. These obstacles can impact production efficiency and product quality.

One common challenge is maintaining consistent material properties throughout the manufacturing process. Variations can lead to performance issues.

To overcome these challenges, it’s critical to implement robust quality control measures. Careful monitoring and adjustments ensure the material meets the required standards.

Quality Control and Process Optimization

Quality control is an essential part of working with PTFE Prepreg. Rigorous testing ensures that each batch meets precise specifications.

Regular inspections during production help identify any deviations early. This proactive approach allows for timely corrections.

Optimizing the lamination process is another key aspect. By refining temperature and pressure settings, manufacturers can enhance both efficiency and product quality.

Conclusion: Embracing PTFE Prepreg for Enhanced Electronics Manufacturing

PTFE Prepreg offers unmatched benefits in electronics manufacturing. Its superior properties enable high-quality PCB production.

Embracing this advanced composite material leads to improved efficiency and reliability. By understanding its applications and optimizing processes, manufacturers can achieve enhanced performance in their products.