- Call Us Today!

- +86 519-88123456

- info@ptfe-pcb-laminate.com

Understanding the Benefits of PTFE Prepreg

12/04/2024Understanding Diclad 880 Laminate Properties

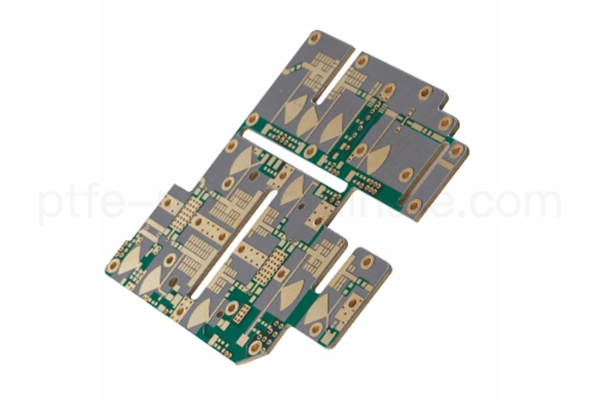

In the realm of high-frequency PCB materials, Diclad 880 laminate stands out. Known for its excellent electrical properties, it’s a crucial component in RF & Microwave applications.

The manufacturing process of Diclad 880, from coating fiberglass fabric with PTFE to pressing the laminate, is intricate. Understanding this process can significantly improve production efficiency and product quality.

This article aims to provide a comprehensive understanding of Diclad 880 laminate. From its key properties to its applications across various industries, we’ll delve into the details.

Whether you’re an Electronics Manufacturing Manager or a PCB Designer, this guide will equip you with the knowledge to optimize your use of Diclad 880 laminate.

The Basics of Diclad 880 Laminate

Diclad 880 laminate is a type of high-frequency PCB material. It’s primarily used in RF and microwave applications due to its superior properties. This laminate is designed to meet the demands of advanced electronic systems.

The core composition of Diclad 880 consists of PTFE and woven fiberglass. PTFE offers low dielectric constant and loss, essential for high-performance circuits. The woven fiberglass adds mechanical strength and stability.

Key features of Diclad 880 include:

- Low dielectric constant (approximately 2.17)

- Low dissipation factor

- Excellent moisture resistance

- High thermal stability

These properties make Diclad 880 ideal for complex multi-layer PCB designs. It’s particularly favored in industries like aerospace, telecommunications, and defense. The material’s resilience against harsh conditions enhances its appeal.

Diclad 880’s compatibility with standard processing techniques adds to its versatility. It supports a range of thicknesses, catering to diverse design requirements. The laminate’s quality depends on precise control throughout its creation process.

Key Properties of Diclad 880 Laminate

Diclad 880 laminate boasts a range of impressive properties. These characteristics set it apart from other materials in high-frequency applications. Understanding these features can help optimize its use in electronic projects.

One significant property is its low dielectric constant. At approximately 2.17, it maintains signal integrity at high frequencies. This ensures reduced signal loss and better performance.

Another crucial feature is the laminate’s low dissipation factor. This property is vital for efficient energy transfer. It also minimizes heat generation in electronic circuits.

Moisture resistance is yet another benefit of Diclad 880. It performs well even in humid environments, ensuring reliability. This makes it a reliable choice in varying conditions.

The laminate also demonstrates high thermal stability. It can withstand a wide range of temperatures without degrading. This stability is crucial for applications in challenging environments.

Furthermore, Diclad 880’s chemical resistance contributes to its durability. It can resist various chemicals, enhancing its lifespan. This is particularly important in harsh industrial settings.

The laminate’s dimensional stability supports high-precision applications. It remains consistent under mechanical stresses. This is vital for maintaining the accuracy of sensitive circuits.

These properties make Diclad 880 highly versatile. Its performance benefits numerous advanced technologies. When choosing materials, these attributes are significant considerations.

Manufacturing Process of Diclad 880 Laminate

The manufacturing process of Diclad 880 laminate begins with the preparation of raw materials. PTFE and woven fiberglass are the primary components. These materials are carefully selected to ensure quality and performance.

Next, the fiberglass fabric is coated with PTFE. This step is crucial for imparting the desirable electrical properties. The process requires precision to achieve uniform coating.

Following the coating, the material undergoes a pressing procedure. It is essential to control the temperature and pressure during this phase. Proper pressing ensures the laminate’s mechanical and thermal stability.

A key focus during manufacturing is maintaining consistency. Strict quality control measures are in place throughout. These steps help in minimizing any defects in the final product.

Lastly, the laminate is cut to specific dimensions. It is then inspected for compliance with industry standards. This ensures that the Diclad 880 meets design requirements before being shipped to customers.

The entire process exemplifies the importance of precision and quality. Manufacturing Diclad 880 demands attention to detail at every stage. This diligence results in a high-performing laminate fit for advanced electronic applications.

Applications and Industries

Diclad 880 laminate finds its use in diverse applications. Its properties make it ideal for RF and microwave circuits. Industries requiring high-frequency PCB materials frequently choose Diclad 880.

In the aerospace sector, Diclad 880 is prized for its reliability. It offers dimensional stability in varied environments. This is crucial for systems operating at high altitudes.

Telecommunications also benefit from Diclad 880’s efficiency. The low dielectric constant supports fast signal transmission. Such performance is vital in modern communication networks.

Defense applications demand robust materials. Diclad 880 provides resilience against environmental factors. Its resistance to moisture and temperature extremes is valuable.

Emerging industries, like IoT, appreciate Diclad 880’s versatility. As technology advances, its role expands. Diclad 880 continues to support innovations across multiple fields.

Comparing Diclad 880 to Other High-Frequency Laminates

Diclad 880 stands out among high-frequency laminates. Its low dielectric constant is a major advantage. This property surpasses many traditional options.

In contrast to standard FR4 materials, Diclad 880 excels in stability. FR4 suffers from higher signal loss at high frequencies. Diclad 880, however, minimizes dissipation factor issues.

Many designers appreciate its mechanical strength. It maintains structural integrity where others might fail. This aspect differentiates it from hydrocarbon-based laminates.

While some PTFE laminates struggle with moisture absorption, Diclad 880 resists it well. This trait enhances reliability in challenging environments. Moisture resistance is essential for durability.

Overall, Diclad 880 offers a balanced combination of electrical and physical properties. Its comprehensive benefits make it a preferred choice. High-frequency applications often demand these specific traits.

Sourcing and Quality Control

Finding a reliable Diclad 880 supplier is crucial. Quality consistency heavily impacts PCB performance. Look for suppliers with solid reputations.

Verify that the supplier meets industry standards. Certifications like ISO can signal a commitment to quality. This is a reassuring factor when sourcing materials.

Inspection processes are vital. Ensure that the supplier implements rigorous quality control. This reduces the risk of defects in laminates.

Consider visiting the supplier’s facility. A firsthand look can provide insights into their manufacturing processes. Transparency is often a good sign.

Proper storage is essential. Ensure laminates are kept in optimal conditions to prevent damage. Good handling practices maintain product integrity.

Design Considerations for Diclad 880 PCBs

Designing with Diclad 880 laminate requires attention to detail. Its electrical properties must be matched to the application’s needs. This ensures optimal performance.

Consider the dielectric constant in your design. Diclad 880 offers a low dielectric constant, useful in high-frequency circuits. It aids in maintaining signal integrity.

Thermal management is another key factor. Ensure efficient heat dissipation in your design. This will help prevent overheating and enhance reliability.

Pay special attention to layer construction. Diclad 880 works well with standard prepregs. This provides flexibility in multi-layer PCB designs.

Finally, consider the mechanical stability. The fiberglass reinforcement contributes to this aspect. It ensures the durability and longevity of the PCB.

Challenges and Solutions in Working with Diclad 880

Working with Diclad 880 presents unique challenges. The material’s PTFE nature can complicate handling. Proper knowledge mitigates these issues.

A common challenge is ensuring stable adhesion. Surface treatments enhance the copper peel strength. This is crucial for effective PCB assembly.

Machining Diclad 880 requires precision. PTFE can be tricky to drill. Using the right techniques and tools minimizes risks.

Managing thermal expansion is vital. The coefficient of thermal expansion should be balanced with other materials. This prevents potential delamination issues.

Additionally, optimizing signal integrity can pose a challenge. Understanding the laminate’s properties helps align design requirements with its capabilities.

Future Trends and Innovations in High-Frequency PCB Materials

The demand for high-frequency PCBs is growing with technological advances. Innovations in material science are crucial in meeting these needs. Emerging technologies like 5G drive these developments.

Sustainability is gaining prominence. Manufacturers are exploring eco-friendly production processes. This aims to reduce the environmental impact of PTFE laminates.

Finally, miniaturization remains a key focus. As electronic devices become smaller, materials like Diclad 880 evolve to support compact and efficient designs. This ensures they meet future technology requirements.

Conclusion: Why Choose Diclad 880 Laminate

Diclad 880 laminate stands out for its excellent electrical properties. It supports high-frequency applications effectively, enhancing signal integrity. Its versatility across industries adds to its appeal.

Choosing Diclad 880 ensures reliability and performance. Its durability and resistance to environmental factors are unmatched. These attributes ensure long-lasting, efficient PCB solutions.

Finally, partnering with a reliable Diclad 880 supplier is crucial. This ensures quality materials that meet specific design needs. Such partnerships help optimize production processes and product outcomes.

Want know our customizable high-frequency PCB solutions? Can’t determine which PCB material is the best choice for your project? Your advanced circuit board project requires specifications which are not listed in the above table? You can also reach our technician by info@ptfe-pcb-laminate.com